Post Grouted Piles

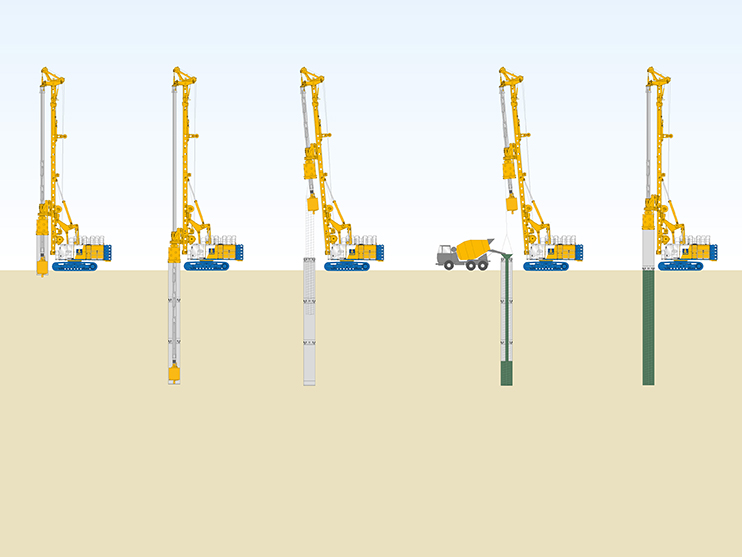

During the past few decades Bauer could successfully develop a piling system, which enabled the nominal bearing capacity of an ordinary bored pile to be increased by improving the contact characteristics at the pile-soil interface.

Post grouted bored piles are now utilized world wide as an effective, economical and feasible alternative to conventional bored piles due to their much higher capacities resulting from increasing their skin friction and their bearing resistance:

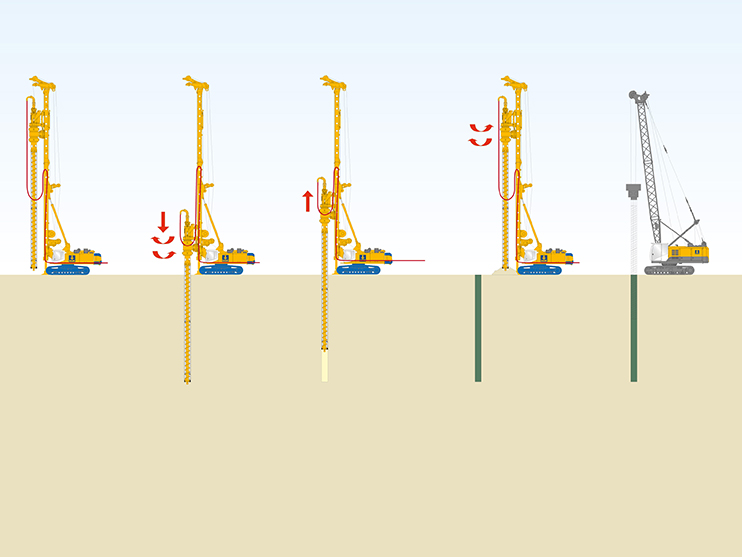

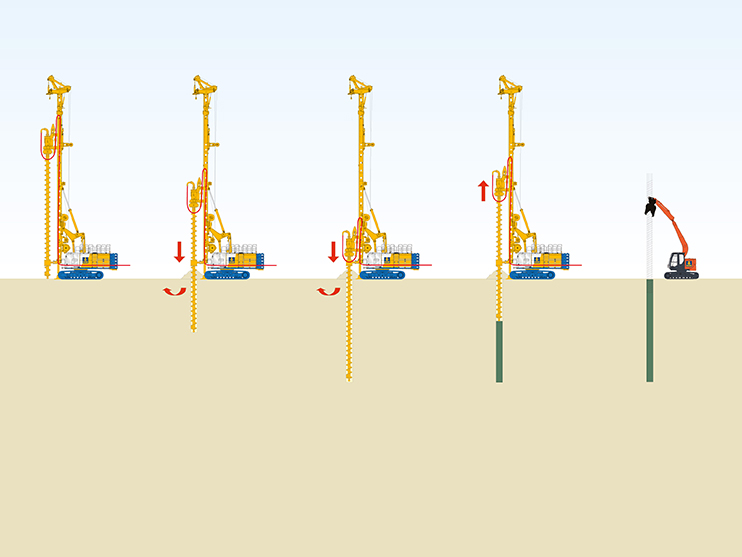

- To improve the skin friction interaction between the pile shaft and surrounding soil, the pile skin is grouted through grouting pipes attached to the reinforcement cage. Due to the pressure generated by the grouting process, a firm interlocking is developed between the pile shaft and surrounding soil along the grouted length.

- The soil at the base of the pile can also be grouted by means of a specially designed steel flat jack, attached to the bottom of reinforcement cage. The steel flat jacks are designed in such a way that the whole of the base area is filled with grout and has the effect of compacting and “pre-stressing” of the base surrounding soil.