Ground Anchors

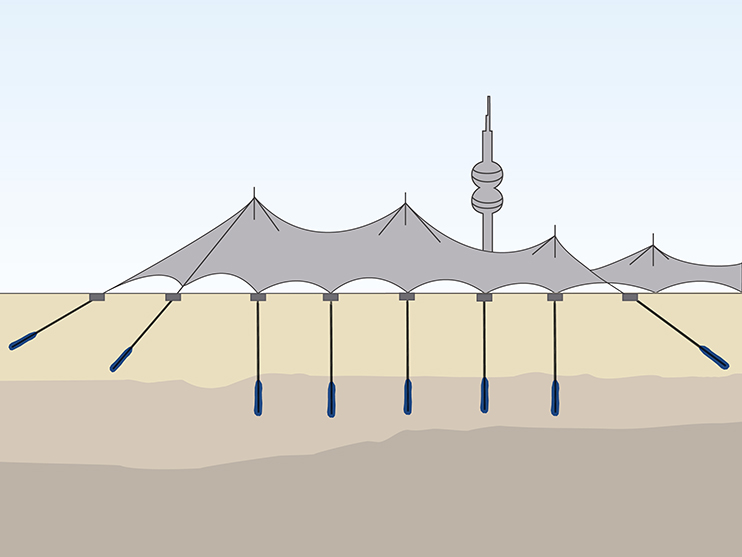

One of Bauer’s great innovations which can be considered the unique solution for supporting retaining structures with rather wide spans, without the need for the obstructive, time consuming and expensive conventional struts method.

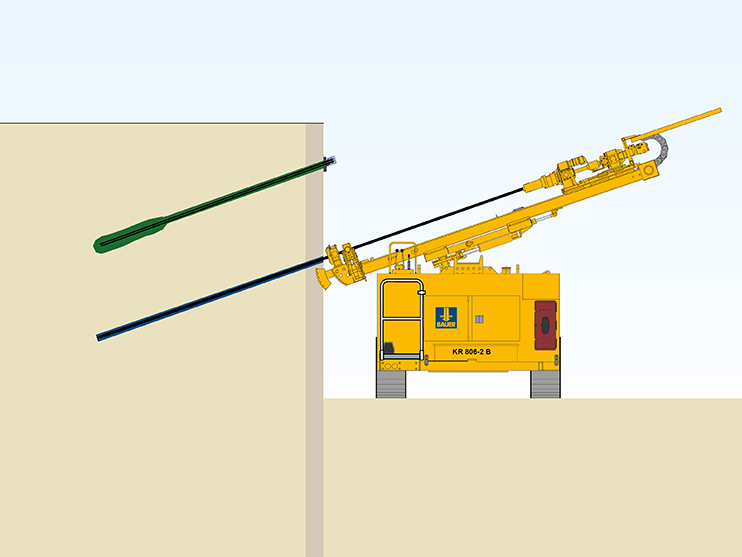

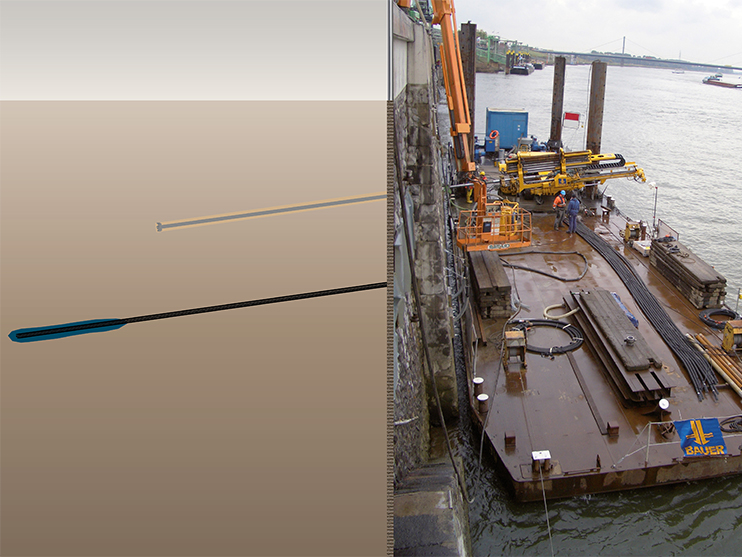

For anchor’s installation, a borehole with a diameter of 70 to 150 mm is rotary drilled by the anchor rig using water / bentonite slurry flushing method. When drilling reaches the required level, the drilling rod is pulled out of the borehole and the anchor is installed manually.

The borehole is filled with cement suspension to the required level through a solid pipe attached to the anchor tendons. Grouting of the anchor’s grout body is carried out after 48 hours through pipes (with sleeves) attached to the anchor’s tendon.

Six to eight days after grouting process is complete, the anchor can be tested / pre-stressed to its required load.

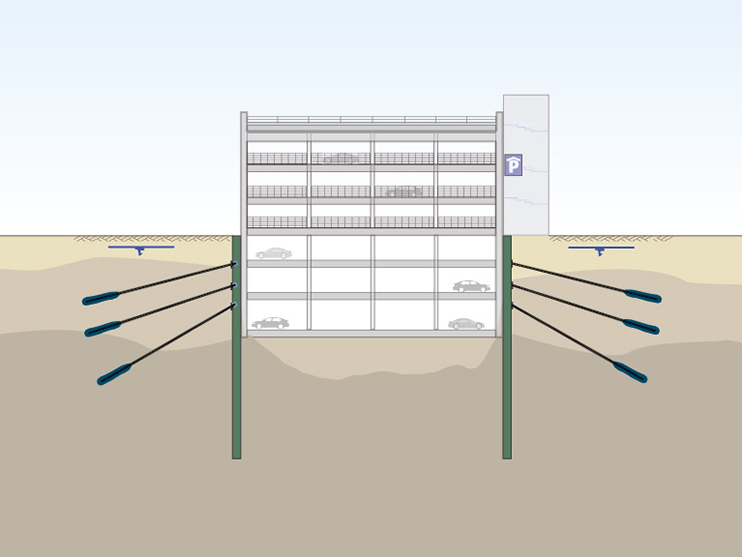

Types of ground Anchors

Temporary anchors, in single-rod or strand anchor configuration, which can be removed fully or partially, are used to secure retaining walls for a maximum of two years. They are quick to install and highly cost-effective. The load-bearing behaviour of each anchor is tested and logged during the acceptance procedure. Strand anchors are delivered to the site in coils, which means they can also be used in tight operating environments.

Permanent anchors are ground anchors usable for longer than two years, and thus part of a permanent structure. Permanent anchors are executed as strand anchors, single-rod corrugated tube anchors or single-rod pressure tube anchors. The steel tendon and anchor head are protected against corrosion by special measures. Each hollow space in the anchor head is filled in with permanently plastic corrosion-proof compound.